Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

AWP-20S

AWP-20S is AUCTECH's advanced collaborative palletizing workstation for light industrial applications. This intelligent, safe, and easy-to-deploy solution offers 20-50kg payloads, a 1.48-1.98m working radius, and ±0.05mm accuracy. Compatible with vacuum grippers and mechanical claws, it achieves 8-12pcs/min efficiency. Designed for plug-and-play deployment, flexible scalability, and low maintenance costs, it enables intelligent upgrades in batch production for industries such as food, pharmaceuticals, and daily chemicals.

- Product Details

-

Download

Features

Easy Operation & Plug-and-Play

User-friendly interface enables quick setup and commissioning, ensuring seamless integration with minimal downtime.

Flexible Palletizing Schemes

Memory function stores multiple configurations for effortless switching between different palletizing plans.

Compact & Flexible Design

Small footprint and adaptable layout make it ideal for facilities with limited space, optimizing workspace utilization.

Customizable Stacking Patterns

Simple parameter input allows free selection of stacking patterns with automatic alignment for precision.

All-Day Operation

Designed for continuous use, saving time, labor, and effort while maintaining high productivity.

Versatile Compatibility

Handles various product types, including boxes and stacks, suitable for multiple industries like food, beverages, and electronics.

Enhanced Safety

Mechanical collision prevention and optional guardrails or light curtains ensure higher safety standards.

Automatic Lifting

Adjusts height up to 2.5 meters according to palletizing needs for efficient, flexible operation.

Parameters

|

Model |

AWP-20S |

|

Weight |

About 600 kg |

|

Payload |

30 kg |

|

Reach |

1480 mm |

|

Maximum palletizing cycle |

≤ 8 pcs/min |

|

Maximum palletizing height |

≤ 2350 mm |

|

Repeat positioning accuracy |

±0.05 mm |

|

Pallet placement form |

Manual, one left and one right |

|

Maximum compatible pallet |

1200 mm × 1000 mm |

|

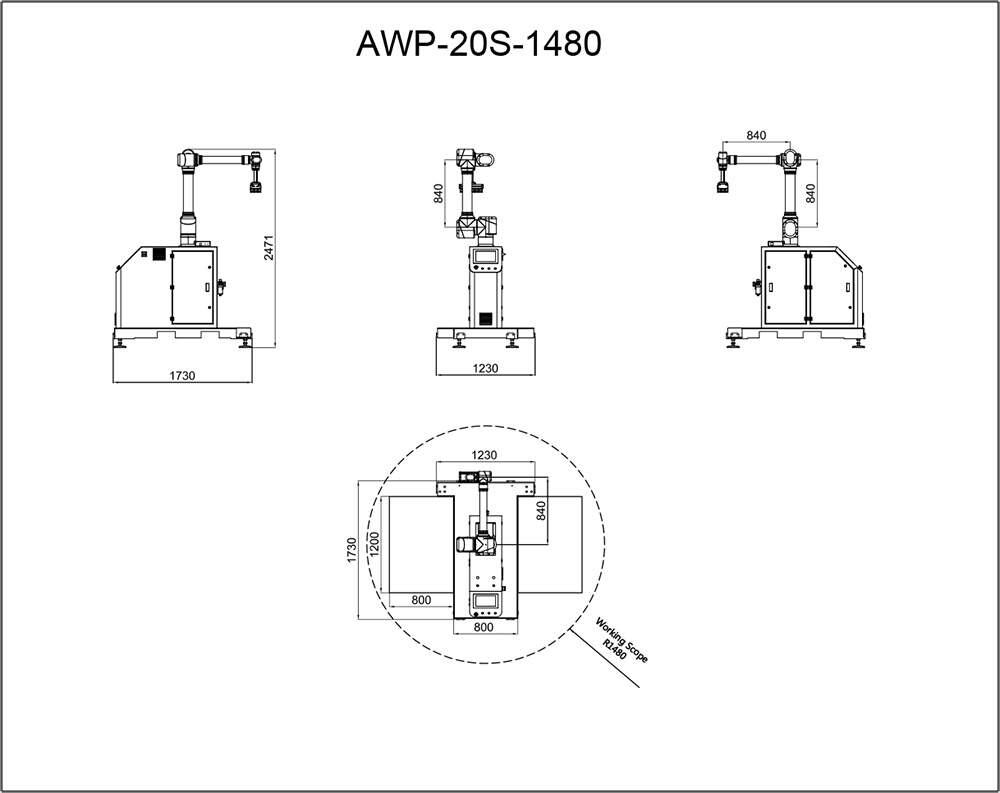

Dimensions |

L1230 mm × W1730 mm × H2471 mm |

|

Dimensions of wooden boxes |

L2200 mm × W1450 mm × H1900 mm |

|

Maximum power |

3.5 KW |

|

Reference gas consumption |

240–460 L/min |

|

Power supply requirements |

AC220V ±10%, 50Hz ±5% |

|

Gas supply requirements |

0.5–0.7 MPa |

|

Communication method |

EtherCAT interface, expansion I/O |

|

IP level |

Robot arm IP53 / Cabinet IP24 |

|

Ambient temperature |

0–50 ℃ |

|

Noise |

< 80 dB |

|

Main color |

Blue gray |

Dimension

Download

-

AWP Series Cobot Palletizing Workstation Catalog-V2.1.pdf